Our state-of-the-art workshop facility as well as dedicated and skilled staff allow us to fabricate steel products to the clients' specifications. From a single customised item to multiple bulk orders. Our experienced team are able to assist in design, manufacture, installation and maintenance as required. Our thorough understanding of industry standards, fully equipped workshop and workforce to match, we have have proven to be very successful within the Mining, Industrial and Civil industries. We understand that all our clients needs and applications are unique, because of this we customise the design process to allow us to manufacture any specific scope to the highest standard.

Fabrication

Contract Engineering

Here at Macquarie Manufacturing we are proud to have an elite team of Designers and Engineers, with specific skill sets, equipped to innovate and modify concepts to suit any Civil, Industrial and Mining application. From a single customised item to multiple bulk orders, Our experienced staff are able to assist in design, manufacture, installation and maintenance as required.

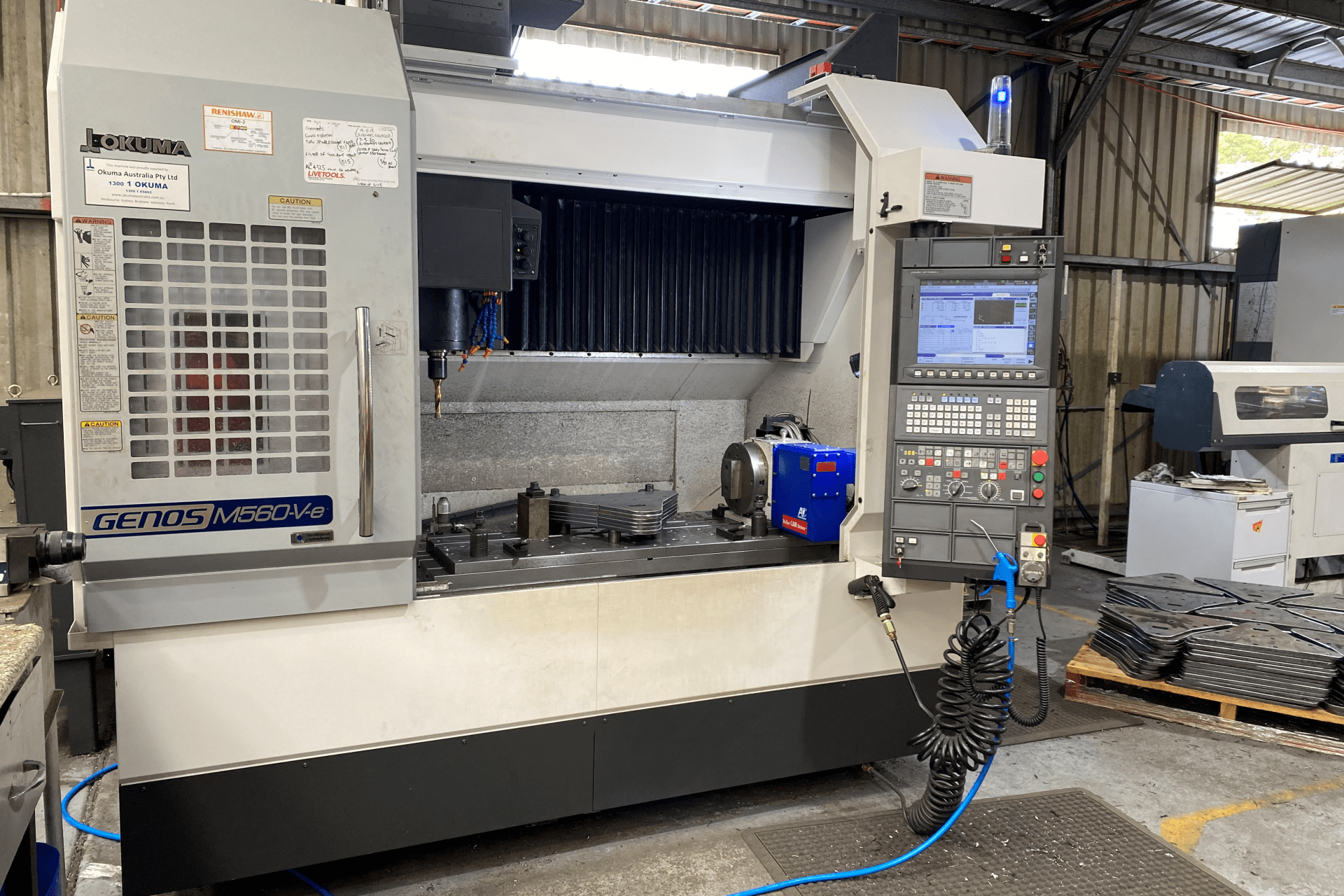

Machining Services

Macquarie Manufacturing Pty Ltd.’s machine shop has the capacity to provide a full package solution for any job, big or small, from design, to fabrication, right through to maintenance and support.

We are committed and focused in continuing to provide the highest quality products and services to schedule and specification.

Our Processing Capabilities

- Ficep Beamline Drill and Saw

- Kinetic 3000 Plasma Cutting System

- Baykal CNC Press-brake

- Saw

Inclusive of precision straight cuts, mitres, hole drilling and tapping.

Precision profile cutting of steel from 0.6mm up to 60mm Auto drilling/tapping turret Bed Dimensions of 14m x 3.4m x 100mm Automated operation for job efficiency

Hydraulically operated 5-axis press 200T capacity 4100mm width capacity Variety of tooling to suit large range of thickness and radii.

Fully automated band saw capable of 400 x 400mm cuts. Bundle and single cutting modes> for cutting efficiency

- Guillotine

- Roundo

- Kingsland Press

- Versa Press

- Drilling

Cutting thickness up to 6mm Length up 3000mm

Roll steel sections to a variety of radii

Variety of tooling to suit large range of punching requirements.

Variety of tooling to suit large range complex bend requirements

Variety of pedestal and Radial drilling machines for all your drilling, tapping, boring and counter sinking requirements.

Our Fabrication Capabilities

- Robotic Welding

- G.M.A Welding

- Plasma Welding

- T.I.G Welding

- Spot Welding

- Sandblasting & Surface coating Dedicated surface coating facilities with large capacity and wide range of available colours and

Panasonic TM1400WG3 -

Fully qualified team of welders with comprehensive catalogue of certified procedures

- Stud Welding Stud welding machine for efficient and strong fasteners.

- On-Site Services We have a comprehensive dedicated suite of tooling to suit on site requirements.

Our Machining Capabilities

- CNC Lathes

- CNC Mills

Okuma LB4000 EX -

Multi Axis Lathe with 12 tool turret capacity

Automatic feed

Full automated machine capable of a large variety of turning/drilling/tapping and boring requirements

Doosan S280N CNC Lathe -

280 x 420mm Turning Capacity.

Okuma Genos M560-V -

Table size of 560 x 1300mm

32 turret capacity

Machining & Drilling capabilities for quenched and tempered and chromium carbide wear plates

- Manual Lathes

- Manual Mills

- Drilling

Hafco CL40A Manual Lathe -

410 x 1000mm Turning Capacity

Additional large and small lathes to suit your turning requirements.

Hafco BM90 Turret Manual Mill - Machining & Drilling capabilities for quenched and tempered and chromium carbide wear plates

HMT and Hafco Radial Arm Drills - Suitable for all drilling, taping, boring and counter sinking requirements.